Business Briefs

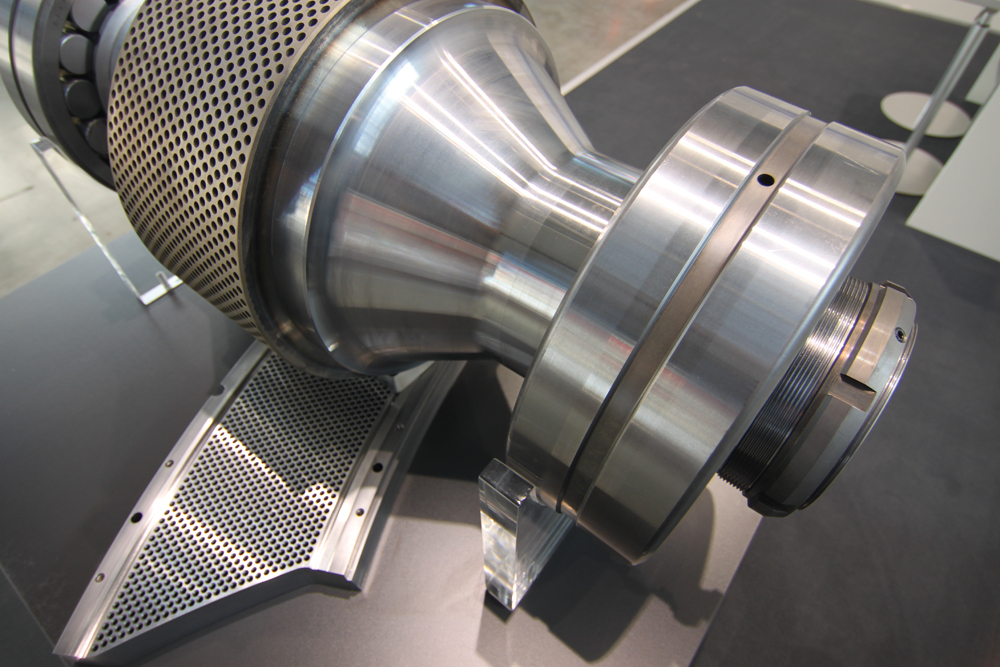

PHOTO: DUST CONTROL TECHNOLOGY

April 25, 2012

BY Staff

Advertisement

Advertisement

Related Stories

A bill introduced by Sen. Cory Booker, D-N.J., would require the U.S. EPA to alter the way it assesses lifecycle GHG emissions from forest biomass. ABEA stresses that any accurate assessment must account for the alternative fate of biomass fuels.

Moisture in wood and biomass operations impacts product as well as equipment, energy usage, production efficiency, downtime and more.

The U.S. DOE has opened a funding opportunity making up to $25 million available to support clean energy technology deployment on Tribal lands. Projects fueled by biomass, biogas, RNG or renewable hydrogen are among those eligible for the funding.

The International Biomass Conference & Expo was held in Richmond, Virginia, in early March.

Meeting net-zero objectives will require operators to increasingly leverage modern technologies and adopt innovative processes.