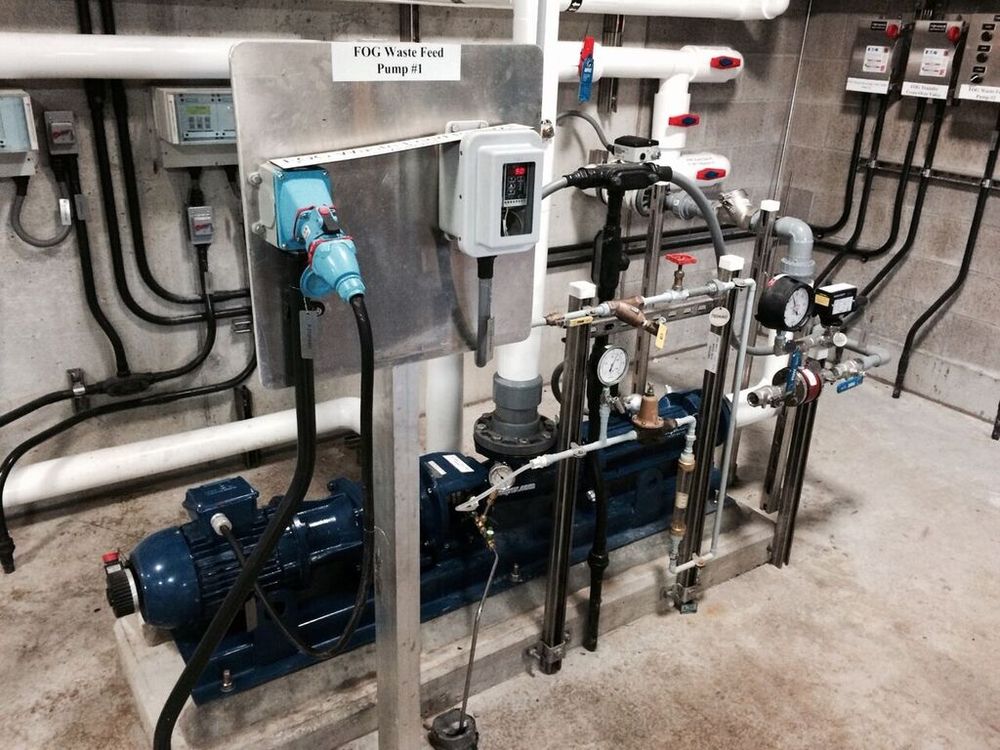

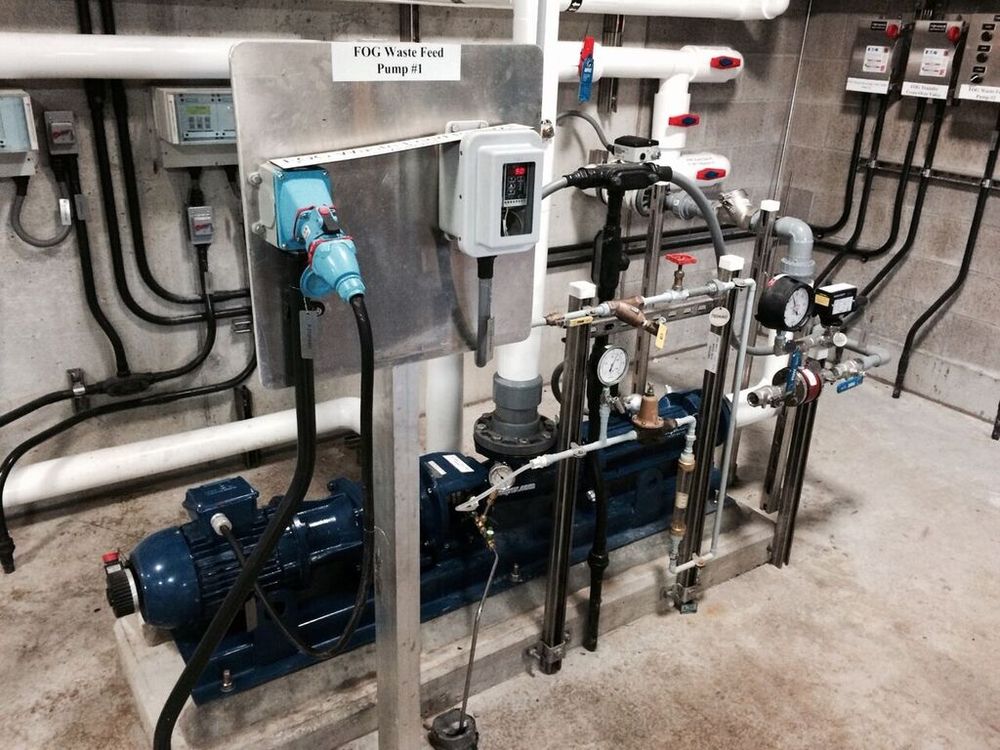

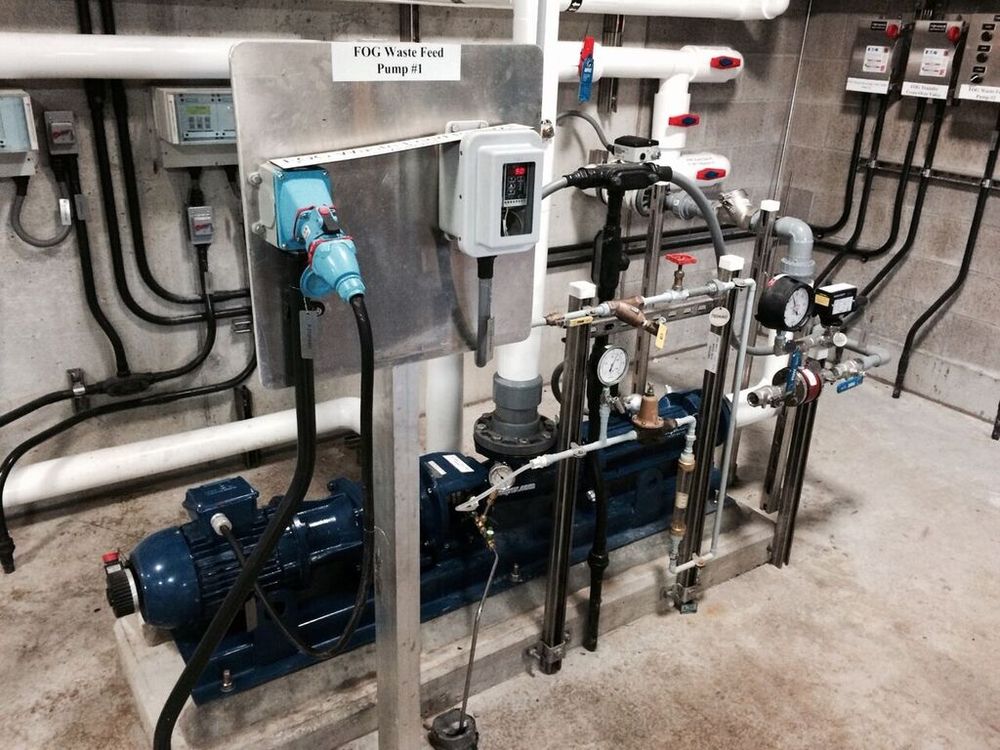

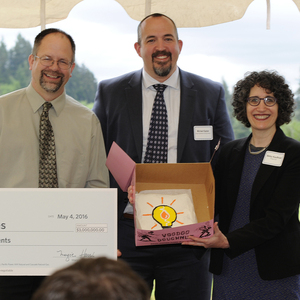

New cogen system triples energy output from biogas at Oregon WWTP

Dale Peterson

May 5, 2016

BY Katie Fletcher

Advertisement

Advertisement

Related Stories

The Transport Project and Coalition for Renewable Natural Gas (RNG Coalition) on April 24 announced that 79%of all on-road fuel used in natural gas vehicles in calendar year 2023 was RNG surpassing the previous year’s record-breaking level.

TotalEnergies and Vanguard Renewables have signed an agreement to create an equally owned joint venture (JV) to develop, build, and operate RNG projects in the U.S. The JV plans to advance 10 RNG projects to construction over the next 12 months.

The USDA on April 23 awarded more than $194 million in loans and grants through the agency’s Rural Energy for America Program. Biogas and bioenergy projects were among those selected to receive funding.

Clean Energy Fuels Corp. on April 23 announced its latest renewable natural gas (RNG) facility at Victory Farms Dairy in Revillo, South Dakota, has successfully completed construction and is injecting pipeline quality RNG into the interstate natural gas infrastructure.

A bill introduced by Sen. Cory Booker, D-N.J., would require the U.S. EPA to alter the way it assesses lifecycle GHG emissions from forest biomass. ABEA stresses that any accurate assessment must account for the alternative fate of biomass fuels.