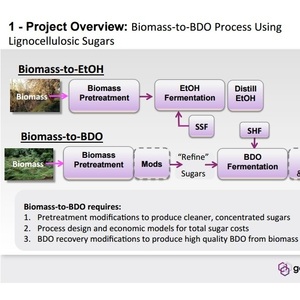

Genomatica advances development of feedstock for biochemicals

Genomatica

June 17, 2015

BY Genomatica

Advertisement

Advertisement

Related Stories

Neste and Lotte Chemical are teaming up to make chemicals and plastics more sustainable. The collaboration will see Neste providing renewable Neste RE, a raw material for chemicals and plastics made from 100% renewable raw materials.

New Energy Blue launches New Energy Chemicals to produce biobased ethylene for carbon-zero SAF, renewable plastics

New Energy Blue on March 18 announced the formation of New Energy Chemicals. In phase one, the biochemical subsidiary will produce biobased ethylene for use in Dow’s renewable plastics. In phase two, the subsidiary will expand to SAF production.

USDA on March 8 celebrated the second annual National Biobased Products Day, a celebration to raise public awareness of biobased products, their benefits and their contributions to the U.S. economy and rural communities.

The USDA Rural Business Cooperative Service on Jan. 24 published proposed rule that aims to update the agency’s Biobased Markets (Biopreferred) Program. A public comment period on the proposed rule is open through March 25.

Lallemand Biofuels & Distilled Spirits on Jan. 23 announced a partnership with Braskem to jointly develop renewable chemicals. The two companies will first explore products for the solvents segment.